1.What is Epoxy Resin?

Epoxy resin is a versatile and durable synthetic polymer widely used in coatings, adhesives, and composites. It consists of two main components: the resin itself and a hardener (curing agent), which chemically react to form a rigid, high-performance material. Epoxy is valued for its strong adhesion, chemical resistance, and durability, making it a popular choice in industrial and consumer applications.

Epoxy resins offer a wide range of beneficial properties, making them a popular choice in various applications

-

Epoxy coatings exhibit excellent mechanical strength, including tensile strength, flexural strength, and impact resistance. This results in durable and long-lasting coatings.

-

Excellent Adhesion: They adhere strongly to various substrates, including metals, glass, wood, and plastics, providing a reliable bond.

-

Chemical Resistance: Epoxy resins are highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and fuels, making them suitable for harsh environments.

-

Electrical Insulation: Epoxies are excellent electrical insulators, making them ideal for applications in electronics and electrical equipment.

-

Low Shrinkage: They exhibit low shrinkage during curing, minimizing stress and distortion in the final product.

-

Versatility:

3.Application

Epoxy resins are extensively used in coatings and paint formulations for various applications:

Used to protect surfaces like steel and concrete in industrial settings, offering resistance to corrosion and chemical exposure

Popular in commercial, industrial, and even residential floor coverings due to its durability and mechanical strength.

Employed in coating parts to protect against environmental factors and mechanical stress

Strengthens and waterproofs concrete in buildings, bridges, and flooring

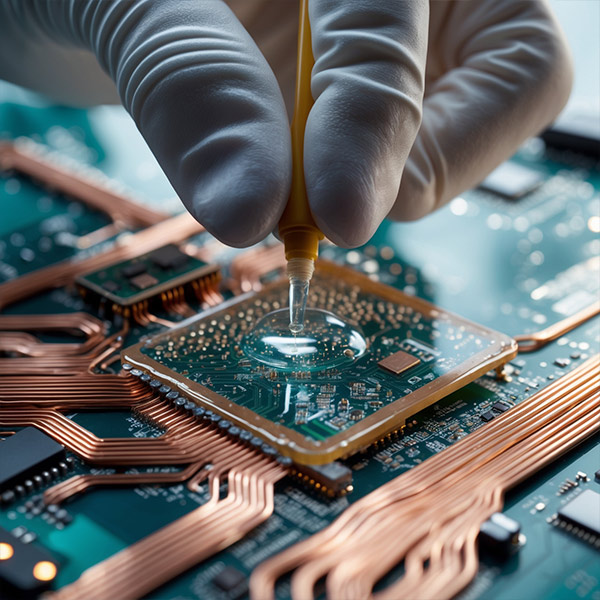

Electronics & Electrical Insulation

Encapsulates circuit boards and components due to its insulating properties

Art & Decorative Coatings

Used in tabletops, jewelry, and resin art due to its glossy, glass-like finish.

4.Limitations or Disadvantages

While epoxy resin offers excellent performance, it has some drawbacks:

-

– Can crack under stress if not modified with flexible additives.

-

UV Degradation – Standard epoxy yellows and breaks down in sunlight unless UV-resistant additives are used.

-

Mixing Required – Requires precise mixing of resin and hardener; incorrect ratios can lead to poor curing.

-

Long Curing Time – Some formulations take hours or days to fully cure, slowing down projects.

-

Health & Safety – Uncured epoxy contains volatile organic compounds (VOCs) and can cause skin irritation; proper ventilation and PPE are needed.

-

Temperature Sensitivity – Extreme cold can slow curing, while heat can shorten work time (pot life).

-

High Cost

5.Typical Types or Categories

Epoxy resins are available in various formulations for different applications:

-

– Standard type, offering strong adhesion and chemical resistance (common in coatings and adhesives).

-

Bisphenol-F Epoxy – Lower viscosity (more flowable) with higher chemical resistance than Bisphenol-A.

-

Novolac Epoxy – Extremely heat and chemical-resistant, used in industrial tank linings and high-temperature applications.

-

Water-Based Epoxy – Low-VOC option for indoor use, though less durable than solvent-based versions.

-

UV-Resistant Epoxy – Contains additives to prevent yellowing and degradation from sunlight.

-

Flexible Epoxy – Modified with rubber or plasticizers to reduce brittleness for impact-resistant coatings.

-

Fast-Cure Epoxy – Hardens in minutes to hours (useful for quick repairs but has a short working time).

-

High-Temperature Epoxy – Withstands extreme heat (for engine parts or industrial equipment).

-

Clear Casting Epoxy

6.Supplier Introduction

A good product relies on excellent and stable suppliers to provide competitive offerings. The following suppliers export to the world’s top 50 paint manufacturers.

Hubei Bestway — also known as Han Epoxy or Wuhan Jiangling Technology Co., Ltd — established in 2008 and operates as a national high-tech enterprise in Hubei, China. With over 17 years’ experience, 14 patents, and a production capacity of ~50,000 tonnes/year (expanding with a new 68,000 m² factory), they specialize in R&D, manufacturing, sales, and customization of epoxy and coating chemicals

NPC’s chemical division offers a broad array of products including bisphenol-A (BPA), maleic anhydride, epoxidized soybean oil, curing agents, and a full epoxy resin line: liquid, solid, novolac, flame-retardant, waterborne, casting, flexible, phenolic hardeners, and PCB inks

Jiangsu Yangnong Kumho Chemical Co., Ltd., established in 2008, is a 50/50 joint venture between China’s Yangnong Chemical Group and Korea’s Kumho Petrochemical, Located in Yizheng, Yangzhou, Jiangsu Province, China, the company focuses on industrial-scale production of epoxy resins—liquid, solid, specialty variants—as well as phenol, BPA, acetone, MIBK, and related materials

7. Epoxy resin products and supplier

| Item No. | Properties | Application | Supplier | Buyer |

|---|---|---|---|---|

| Epoxy Resin 901X75 | Excellent chemical resistance | Anti-corrosion coatings | HUBEI BESTWAY TECHNOLOGY CO | ALLIED PAINT INDUSTRIES LIMITED |

| Epoxy Resin 128 | Has excellent bonding properties, chemical resistance, thermal stability | Suitable for bonding, electrical insulation materials, civil engineering, waterproof reinforcement, decorative coatings, road traffic, food container anticorrosion | HUBEI BESTWAY TECHNOLOGY CO | KAIZEN PAINT (PRIVATE) LTD |

| Hanamine 1816 | An extremely low viscosity modified cycloaliphatic amine epoxy hardener used with liquid epoxy resins at room temperature | Used as curing agent for epoxy floor self-leveling or thin coating surface,mortar flooring. | HUBEI BESTWAY TECHNOLOGY CO | NIPPON PAINT PAKISTAN (PRIVATE) LTD |

| YN 1828 | Excellent bond strength with the surface of metal and non-metallic materials, and is featured by good dielectric properties, small hardeningshrinkage, good product size stability, high hardness, good flexibility, and good stability against alkali and most solvent | Industrial coating | JIANGSU KUMHO YANGNONG CHEMICAL CO., LTD | JOTUN PAINTS VIETNAM COMPANY LTD |

| YN2301X75 | With advantages like good adhesion, good resistance to acid, alkali, salt, weather | Widely used in coatings, electrical, construction | JIANGSU KUMHO YANGNONG CHEMICAL CO., LTD | JOTUN INDIA PRIVATE LIMITED |

| NPEL-128 | NPEL-128 is a liquid resin,which is manufactured from bisphenol-A and epichlorohydrin | Always offers quality and high purity properties in applications,such as maximun mechanical strength,good chemical resistance and excellent heat resistance | NAN YA PLASTICS CORPORATION | BERGER PAINTS PAKISTAN LTD |

| NPSN-901X75 | Cured with polyamide or polyamine hardeners, it provides good levels of chemical resistance and physical properties. | Used in anticorrosive paint. | NAN YA PLASTICS CORPORATION | NIPPON PAINT PAKISTAN (PRIVATE) LTD |

| NPES-903 | Is a medium molecular weight solid epoxy resin, which designed especially for powder coating. | The grade is combined with titanium dioxide and dicyandiamide hardener in powder coating system. After storing at 200℃ or above, it provides high gloss, excellent flexibility and smoothness | NAN YA PLASTICS CORPORATION | BERGER PAINTS PAKISTAN LIMITED |