1.

dye is a colored substance that chemically bonds to the material it is applied to. Unlike pigments, which are typically insoluble particles, dyes are usually soluble in water or other solvents and form molecular interactions with the substrate. This allows them to provide long-lasting, uniform coloration

2.

Dyes can be classified based on their chemical structure, solubility, and application method. Some common categories include:

2.1 Acid Dyes

Acid Dyes are a type of water-soluble anionic dye that bond with fibers in acidic environments. They are commonly used to dye protein-based fibers (such as wool and silk) and synthetic fibers (such as nylon).

Acid dye supplier:Tianjin XiangRui Dyestuff Co., Ltd.

Tianjin XiangRui Dyestuff Co., Ltd., established in 1998, is a leading dye manufacturer based in North China. Specializing in Direct, Acid, and Basic Dyes, the company boasts an annual production capacity of 18,000 tons. Its products are widely utilized across various industries, including textiles, leather, paper, plastics, agriculture, and coatings. With a strong emphasis on quality, research and development, and customer service, XiangRui has expanded its market presence to over 30 countries worldwide.

2.2 Basic dyes

Basic Dyes, also known as Cationic Dyes, are a type of positively charged water-soluble dyes. They are referred to as “cationic dyes” because their molecules can form cations (positive ions) in solution.

Basic dye supplier:Tianjin Sunrise Import & Export Co., Ltd

Tianjin Sunrise Import & Export Co., Ltd. is a prominent Chinese manufacturer and exporter of high-quality dyes and pigments. Specializing in sulphur dyes for denim, liquid dyes for paper, and direct, acid, and basic dyes for textiles and leather, the company is committed to strict quality standards and sustainability. With a global presence, Sunrise serves clients across multiple industries, offering tailored solutions and comprehensive customer support

2.3 Reactive Dyes

Reactive Dyes are a class of dyes that can form covalent bonds with functional groups in fibers, resulting in a strong and durable attachment of color to the fiber. These dyes exhibit excellent wash and light fastness.

Reactive dye supplier:Yuanli Chemical Group Co., Ltd.,

Yuanli Chemical Group Co., Ltd., established in February 2003, is a private joint-stock enterprise listed on the Shanghai Stock Exchange. Specializing in high-end fine chemicals, bio-based products, and new materials, the company operates four production bases across China and maintains subsidiaries in Europe. With a strong emphasis on R&D and innovation, Yuanli holds 97 patents and exports its products to over 60 countries, serving diverse industries such as transportation, healthcare, electronics, and new energy.

2.4 Direct Dyes

Direct Dyes are a class of water-soluble dyes that can dye fibers directly without the use of a mordant. They are mainly suitable for cellulose fibers such as cotton, linen, and viscose.

Direct dye supplier:Alan Chemical Industries LTD

Alan Chemical Industries LTD is a professional manufacturer and exporter specializing in dyestuffs and various auxiliaries for the paper, food, textile, and plastic industries. With over a decade of experience, the company serves markets across South Asia, Europe, and the Americas. To better cater to its South Asian clientele, AlanChem established a branch in Ho Chi Minh City, Vietnam, in 2016

2.5 Vat Dyes

Vat Dyes are a class of water-insoluble dyes that must be chemically reduced into a soluble leuco form during the dyeing process. This soluble form penetrates the fibers and is then oxidized back to its original insoluble form, becoming fixed inside the fiber. As a result, these dyes offer excellent wash and light fastness.

Vat dye supplier:WUXIN GROUP

WUXIN GROUP is a professional enterprise involved in manufacturing and marketing high-quality dyes and pigments for a wide range of customers both domestically and internationally. Established in 1989, the company has become well-known in the denim industry, previously recognized as Anping County Wuxin Chemical Dyes Co., Ltd.

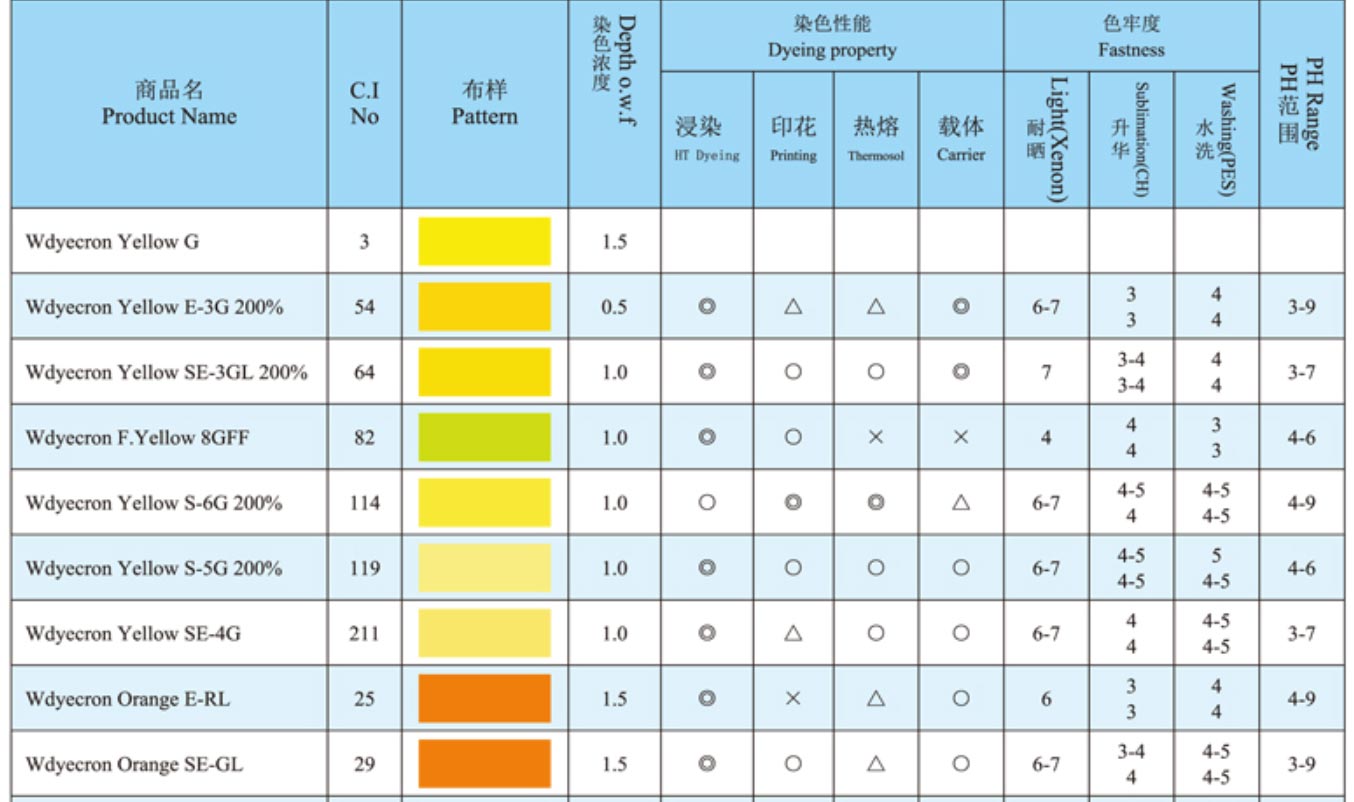

2.6 Disperse Dyes

Disperse Dyes are a type of non-ionic dyes that are insoluble in water, mainly used for dyeing hydrophobic synthetic fibers such as polyester and acetate fibers. They must be dispersed into fine suspended particles in water with the help of dispersing agents to carry out dyeing.

Disperse dye supplier:Hangzhou Weiyi Chemical Co., Ltd

Hangzhou Weiyi Chemical Co., Ltd, founded in 1992 and based in Hangzhou, Zhejiang, specializes in dyes, pigments, intermediates, and textile auxiliaries. Formerly known as Hangzhou Xinsheng Chemical, the company focuses on producing high-quality, eco-friendly chemical products and maintains long-term partnerships through reliable service and competitive pricing.

2.7 Azo Dyes

-

Azo Bond (-N=N-): The core structure of azo dyes, usually linking two aromatic rings.

-

Wide Color Range: Especially reds, oranges, and yellows.

-

Synthetically Produced: Created through a process called azo coupling, which involves a diazonium salt reacting with a coupling component.

-

Cost-Effective: Relatively easy and economical to manufacture.

-

Variable Fastness

Azo dye supplier:He Dye Chem Co., Ltd.,

He Dye Chem Co., Ltd., operating under the brand HEDAI, is a reputable Chinese manufacturer and supplier of high-quality dyes and dye intermediates. Established in 2008, the company specializes in providing a wide range of dye products for various applications, including textiles, leather, paper, plastics, inks, and furniture materials

3.Compared to dyes, pigments have the following advantages:

- Superior Light and Weather Resistance Pigments generally offer much better lightfastness and weather resistance than dyes, making them ideal for outdoor applications or products exposed to sunlight.

- Wider Substrate Compatibility Pigments can be used on a variety of surfaces including plastics, metals, ceramics, and coatings, whereas dyes typically require specific fiber or material compatibility.

- Color Stability and Non-Migratory Properties Pigments are insoluble and tend to stay in place, preventing bleeding or migration, which is common with dyes in wet or humid conditions. This leads to more stable and durable coloration.