1.What is Acrylic Resin

Acrylic resins are synthetic polymers widely used in coatings, paints, adhesives, and plastics. They are derived from acrylic acid, methacrylic acid, or related compounds. Their versatility stems from the ability to tailor their properties by selecting different monomers and polymerization methods. This article will explore the key characteristics, common uses, limitations, and typical categories of acrylic resins.

Acrylic resins possess a unique combination of properties that make them desirable for many applications:

-

Acrylic resins exhibit outstanding resistance to sunlight, UV radiation, and environmental degradation. They do not yellow or degrade significantly upon prolonged exposure, making them suitable for outdoor applications.

-

Transparency and Color Retention: They are inherently transparent and maintain their clarity over time. They also offer excellent color retention, ensuring that painted surfaces retain their original hue.

-

Durability: Acrylic resins offer a good balance of hardness, flexibility, and overall durability. They provide coatings with good scratch resistance and impact strength.

-

Adhesion: They adhere well to a variety of substrates, including metal, plastic, wood and other coatings.

-

Versatility: Acrylic resins can be formulated into various forms, including solutions, emulsions, and solids, to meet specific application requirements.

-

Chemical Resistance:

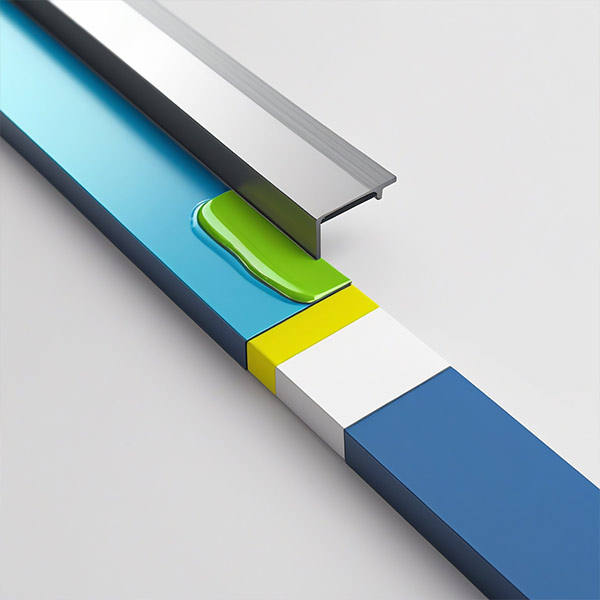

3.Application

Acrylic resins are extensively used as binders in paints and coatings due to their excellent properties. Some common applications include:

Employed in automotive paints and clearcoats to provide a glossy, durable, and UV-resistant finish.

Used in various industrial applications, such as machinery, equipment, and metal structures, offering protection against corrosion and environmental factors.

Their strong bonding power makes acrylic resins suitable for adhesives and sealants used in construction, electronics, and automotive industries.

Specialty Coatings:

Utilized in specialized coatings such as UV-curable coatings, powder coatings, and water-based coatings for specific performance requirements.

4.Limitations or Disadvantages

Despite their numerous advantages, acrylic resins also have certain limitations:

- Solvent Sensitivity: Some acrylic resins can be sensitive to certain solvents, which may cause them to soften, swell, or dissolve.

- Brittleness: Solid acrylics should not be used to support extremely heavy loads, as it becomes brittle under excessive weight.

- Scratch Resistance: Uncoated acrylic scratches more easily than glass and may require the addition of scratch-resistant additives for demanding applications.

- Temperature Sensitivity: Some acrylic resins may soften at high temperatures or become brittle at very low temperatures, limiting their use in extreme environments.

- Cost: Depending on the specific type and formulation, acrylic resins can be more expensive than other resin options like alkyd resins.

- Toxicity: Acrylic resin dust and vapors can be harmful, so it is important to work in a well-ventilated area and wear protective gear.

- Durability: Acrylic resin may not be as durable as alkyd resin and can be prone to scratches and abrasions.

5.Typical Types or Categories

Acrylic resins can be broadly classified into the following categories:

- Thermoplastic Acrylic Resins: These resins soften when heated and can be repeatedly reshaped. They are commonly used in applications where flexibility and ease of processing are required. Examples include acrylic lacquers and films.

- Thermosetting Acrylic Resins: These resins undergo irreversible chemical changes upon curing, forming a cross-linked network. They offer excellent resistance to solvents, chemicals, and heat. They are often used in high-performance coatings and adhesives.

- Solution Acrylic Resins: These resins are dissolved in a solvent. Solventborne acrylic resins have homogeneous film with excellent workability and fast drying properties.

- Emulsion Acrylic Resins (Acrylic Latex): These are water-based dispersions of acrylic polymers. They are environmentally friendly due to low VOC emissions and are widely used in architectural paints.

- Water-Reducible Acrylic Resins: These resins can be thinned with water. Water reducible acrylic resins typically have acid numbers of 40 to 60.

- Acrylic Polyols: Designed for use in two-component systems, these resins crosslink with isocyanates to form durable coatings.

- Styrene-Acrylic Resins: These are complex acrylic resins where styrene monomers are added to reduce cost. While they offer improved water and alkali resistance, they may be prone to yellowing.

- Self-Crosslinking Resins: These acrylic resins contain functional groups that enable them to crosslink upon heating, enhancing hardness, gloss, and chemical resistance.

6.Supplier Introduction

A good product relies on excellent and stable suppliers to provide competitive offerings. The following suppliers export to the world’s top 50 paint manufacturers.

Eternal Materials Co., Ltd. (長興材料工業股份有限公司), founded in 1964 and based in Taiwan, is a global materials science company specializing in synthetic resins, specialty materials, and electronic materials. With a strong R&D and global manufacturing footprint (including facilities in Japan, China, the U.S.), it develops eco-friendly products and advanced solutions for electronics, coatings, medical, and energy sectors

Add & Poly Resin Industrial Co., Ltd. (加合樹脂企業), founded in 1977 and based in Taiwan, specializes in the production of industrial-grade, solvent-based acrylic resins primarily for coatings and paints. Their product line includes thermoplastic and thermosetting acrylic resins as well as polyurethane (PU) polyols. Serving demanding industrial markets, the company continuously develops and adapts its formulations to meet evolving performance and environmental standards

Shanghai Yoo‑Point Chemical Manufacturing Co., Ltd., part of the Yoo‑Point Group, was established in 2003 and is based in Shanghai, China. The company operates two resin production plants with a combined annual capacity of approximately 150,000 tons. Specializing in a broad portfolio of coating resins—epoxy, acrylic, amino, polyester, alkyd, and waterborne types—it supports industries such as building, decoration, industrial coatings, adhesives, and wind power

7. Acrylic Resin supplier and buyer

| Item No. | Properties | Application | Supplier | Buyer |

|---|---|---|---|---|

| ETERAC 7306-XP-60 | High gloss, fast drying, chemical resistance, durability | Color adjustment for varnish or color-paste | ETERNAL MATERIALS CO., LTD | AKZO NOBEL PAKISTAN LIMITED |

| ETERAC 7612-1 | Alkali and water resistance, pigment dispersion, and gloss retention | stone paint | ETERNAL MATERIALS CO., LTD | JOTUN INDIA PRIVATE LIMITED |

| ETERAC 7256-BR-60 | Self cross-linking | Can coating, White coating | ETERNAL MATERIALS CO., LTD | NIPPON PAINT (INDIA) PRIVATE LIMITED |

| ACRYLIC RESIN U-1906A | Acrylic polyol. It exhibits excellent adhesion and is soluble in solvents such as n-BAC, xylene & toluene | suitable for polyurethanes & ABS and metals coatings | ADD&POLY RESIN INDUSTRIAL CO LTD | NIPPON PAINT VIETNAM(HANOI) CO LTD |

| ACRYLIC RESIN U-2103 | U-2103 is a medium hydroxy-value acrylic polyol that is fast drying, has high gloss and hardness, has good adhesion on ABS, PS, and PC substrates | well suited for ABS, PC, and PS plastic one layer coatings. | ADD&POLY RESIN INDUSTRIAL CO LTD | NIPPON PAINT VIETNAM(HANOI) CO LTD |

| ACRYLIC RESIN U-1908R | U-1908R is a multi-purpose acrylic polyol resin with good pigment dispersion. It is fast drying, has good aluminum pigment orientation, and good adhesion. | well suited for 2KPU type or baking enamel type base coats on metal, and as 2KPU type or TPA type base coats on plastics. | ADD&POLY RESIN INDUSTRIAL CO LTD | NIPPON PAINT VIETNAM(HANOI) CO LTD |

| ACRYLIC RESIN YP23-70J | High gloss, fullness,leveling, wetting and dispersion | Two-component PU paint,industrial paint, container paint | SHANGHAI YOO POINT CHEMICAL MANUFACTURING CO LTD | JOTUN PAINTS VIETNAM COMPANY LTD |

| ACRYLIC RESIN YP23-80J | High solid content ,good weather resistance , yellowing resistance,compatibility | Two-component polyurethane coatings | SHANGHAI YOO POINT CHEMICAL MANUFACTURING CO LTD | JOTUN PAINTS VIETNAM COMPANY LTD |