High-Speed Dispersers, Bead Mills, Three-Roll Mills—along with some advanced options like High-Shear Emulsifiers, Planetary Mixers, and Vacuum Dual-Shaft Mixers

1.

A high-speed disperser uses a rapidly rotating disc (typically 1000–3000 rpm) to generate strong shear forces and turbulence. This helps to wet and initially break down pigment agglomerates into the liquid system.

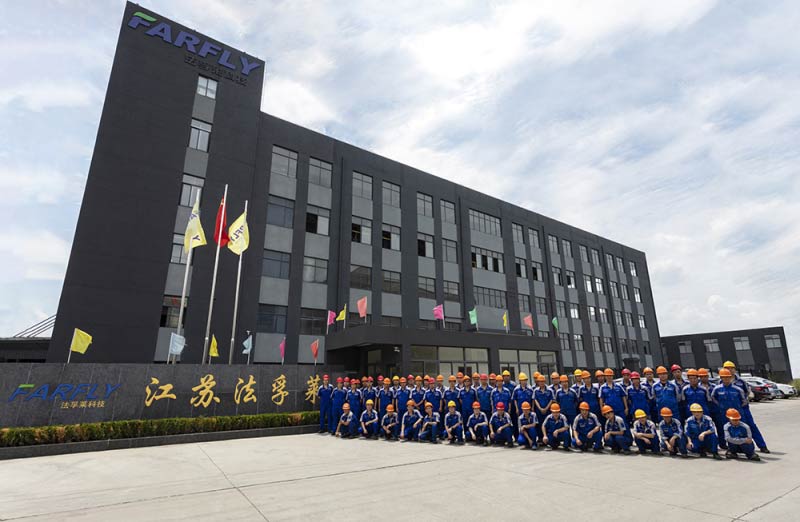

High speed disperser supplier :Jiangsu Farfly Industrial Intelligent Equipment Co., Ltd

Farfly Energy Technology Co., Ltd. is a Chinese company founded in 2003, specializing in chemical machinery and equipment manufacturing. They provide products such as mixers, dispersers, emulsifiers, and reactors, catering to industries like coating, paint, ink, agrochemical, and more. Farfly also offers integrated services, including design, installation, and system optimization. Their products are sold in over 80 countries, with a focus on high-quality, efficient, and stable solutions.

Main Products

Bead mills grind pigments using small grinding beads (e.g., zirconia) in a sealed chamber. The media collides with pigment particles under high-speed agitation to achieve fine dispersion..

Bead mill supplier :SHANGHAI ELE MECHANICAL

Shanghai ELE Mechanical and Electrical Equipment Co., Ltd., established in 1996, is a global processing and service center for ELE® products. With integrated Swiss finishing technology and a worldwide parts procurement system, ELE® offers high-quality products and professional technical support globally. Their core products include sand mills, emulsification equipment, wet grinding machinery, mixing equipment, dry powder mixers, and process integration for chemical industries, including complete plant solutions and custom production lines.

Main Products

3. Three Roll Mill

Three horizontal rollers rotate in opposite directions. The pigment slurry is fed between the rollers, where it is subjected to high shear and compression, resulting in ultra-fine dispersion.

Three roll mill supplier :CHANGZHOU ZILI INTELLIGENT EQUIPMEN

Changzhou Zili Intelligent Equipment Co., Ltd. is a leading manufacturer specializing in machinery for industries like inks, coatings, cosmetics, and more. With a history rooted in Wujin Mining Machinery Factory, Zili produces high-quality equipment including three roll mills, ball mills, and nano sand mills. Serving global markets, Zili is recognized for innovation, quality, and social responsibility, with certifications such as ISO9001:2015 and CE.

Main Products

Uses a rotor-stator mechanism to create intense shear and mixing, ideal for breaking down pigment clusters and emulsifying complex systems.

High shear emulsifier supplier :FLUKO EQUIPMENT SHANGHAI CO LTD

Fluko Equipment Co., Ltd. specializes in providing high-shear mixing, dispersing, emulsifying, and homogenizing solutions for various industries, including chemicals, food, pharmaceuticals, and new materials. With over 20 years of experience, Fluko offers innovative mixing technologies and customized solutions, from laboratory to industrial scale. The company is recognized for its cutting-edge equipment and commitment to customer satisfaction.

Main Products

Equipped with dual or multi-blade agitators that rotate both around the vessel and on their own axes, creating planetary motion for strong kneading and mixing.

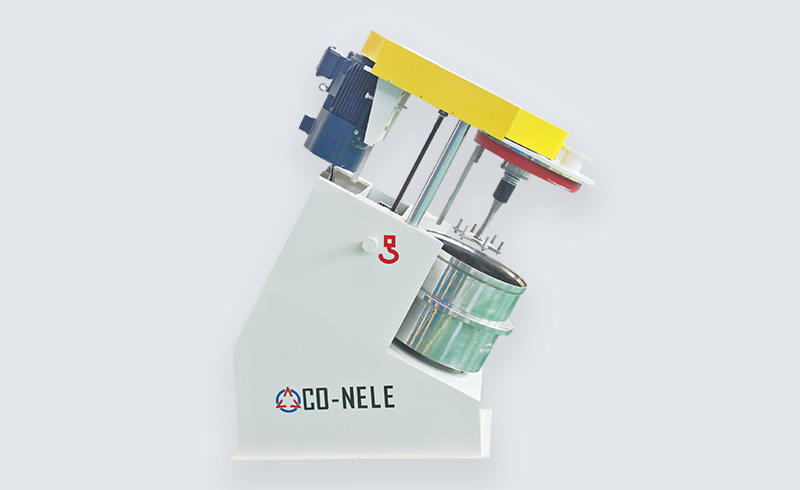

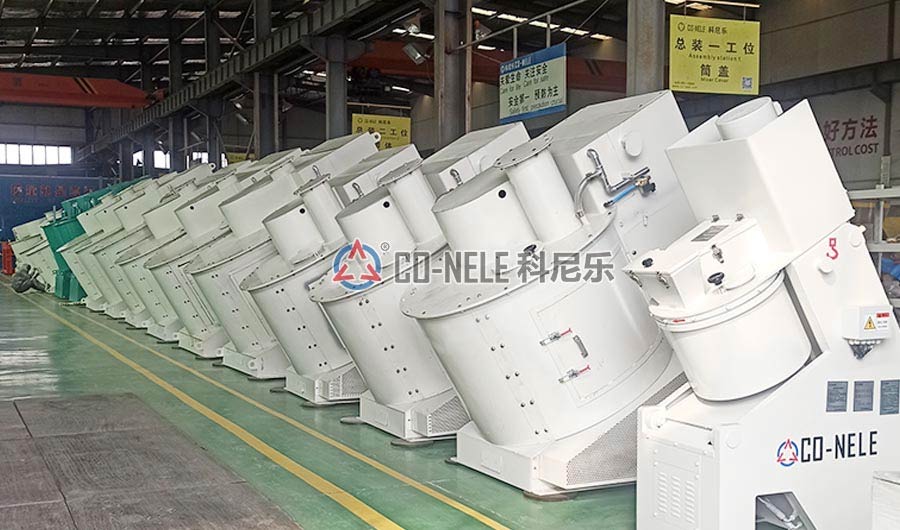

Planetary Mixer Supplier:CO-NELE

CO-NELE is a leading Chinese manufacturer of industrial mixers, with over 26 years of experience in producing intensive mixers, planetary concrete mixers, and granulating equipment. The company holds over 100 patents and serves diverse industries including concrete, refractory, ceramics, and chemicals. Known for innovation and quality, CO-NELE delivers customized mixing solutions globally from its own factory.

Main Products

6.Dual-Shaft Mixer / Vacuum Mixer

Combines a low-speed anchor blade and a high-speed disperser within one vessel. This allows simultaneous scraping, folding, and high-speed dispersion. Vacuum function helps remove entrapped air.

Supplier:Ginhong

Ginhong is a leading China-based manufacturer specializing in industrial mixers and blenders. With over 16 years of experience, the company offers advanced mixing solutions tailored for industries such as cosmetics, pharmaceuticals, food, and chemicals. Ginhong is renowned for its commitment to quality, customizable designs, and exceptional customer service, providing both standard and bespoke mixing equipment to clients worldwide

Main Products

Summarise

| Equipment | Dispersion Level | Viscosity Range | Cleaning Ease | Ideal Use |

| High-Speed Disperser | ★☆☆☆☆ | Low–Medium | ★★★★★ | Pre-mixing, basic pigment dispersion |

| Bead Mill | ★★★★☆ | Medium–High | ★★☆☆☆ | Fine grinding, continuous production |

| Three-Roll Mill | ★★★★★ | High | ★☆☆☆☆ | Precision dispersion for inks/pastes |

| High Shear Emulsifier | ★★★★☆ | Medium–High | ★★☆☆☆ | Nano dispersion, emulsions |

| Planetary Mixer | ★★★☆☆ | High | ★★☆☆☆ | Paste-level mixing, adhesives |

| Vacuum Dual-Shaft Mixer | ★★★★☆ | Medium–Super High | ★★☆☆☆ | Thick pastes, degassed high-performance slurries |